One of the most important steps to finding the right backpack is understanding the pros and cons of popular backpack materials. Are you looking for durability, water-resistance, something lightweight — or all of the above? To help inform your backpack decision, we break down the common materials that backpacks are made of in this comprehensive guide.

Reading Time: 10 minutes |

Subscribers: 23,588 |

Common Backpack Body Materials

The exterior fabric of a backpack is crucial for durability and protection. It shields its contents from weather and damage while ensuring long-lasting performance. Let’s review the fabrics backpacks are made of, as well as their pros and cons.

Natural Materials:

1. Cotton

Given its versatility, durability and natural softness, cotton has been an essential textile for centuries. Even though cotton fabrics come from the same source plant, different manufacturing techniques result in fabrics with different properties. Let’s look at two cotton fabrics that are often used in backpacks.

2. Cotton Canvas

Cotton Canvas was once a leading backpack material. Cotton canvas features thicker yarn compared to regular cotton, making it tougher but less soft. To increase its water resistance, canvas was traditionally coated in wax, whereas nowadays synthetic materials are often woven in for this purpose. In terms of popularity, synthetic materials have largely replaced cotton canvas due to their superior lightness and durability.

3. Duck Canvas

An even more durable and heavy-duty version of cotton canvas, duck canvas (or cotton duck) is often used in industrial settings and workwear fabrics. Duck canvas is more tightly woven than cotton canvas, and features two yarns woven together in the warp. Although it’s not the lightest material, a duck canvas backpack will stand up to wear and tear.

4. Leather

Similar to cotton canvas, leather was once a predominant backpack material. Leather is super tough, great looking, and can last for many years. However, it's heavy, expensive and requires proper care for it to stay in good condition. These cons have moved leather from a popular backpack material to a material that is mainly used for high fashion backpacks or for durable backpack accents, such as fasteners, zipper pull-tabs, or high-abrasion bottom panels.

5. Hemp

Hemp backpacks are a great alternative to cotton-based backpacks due to their strength, durability, breathability and eco-friendliness. Hemp fibers are more abrasion-resistant and stronger than cotton fibers — after all, hemp was once used to make ship sails and rigging.

Along with its strength comes the fact that hemp doesn’t stretch out under heavy loads. Its natural antimicrobial properties make it extremely resistant to mold, fungi and mildew. And, to make the pros list even longer, hemp surpasses many fabrics in its UV resistance — meaning it won’t break down easily in the sun.

Other benefits to hemp are its sustainable qualities. Hemp is a much hardier plant than cotton. For example, hemp only needs one-third of the water that cotton needs. It also requires significantly less herbicides and pesticides.

But every fabric has a few cons. Hemp is rougher to the touch compared to cotton, and often has a more rugged look. However, hemp can get softer with each wash. And higher thread counts, or hemp woven with other natural materials, can also make the fabric softer.

Man-Made Materials:

1. Nylon (Fiber)

Nylon was the first synthetic thermoplastic polymer to successfully reach the market. Given its lightweight, durable, abrasion-resistant, and versatile qualities, it became popular in wartime applications like parachutes. As it turns out, these qualities also work remarkably well in backpacks. As such, Nylon has become one of the most common materials used in backpacks today. Let’s explore some common nylon fabric variations.

A. Ballistic Nylon

Ballistic nylon is a type of nylon fabric that utilizes a 2x2 basketweave of high denier nylon fibers, making it one of the toughest fabrics on the market. Ballistic nylon was originally created, as the name suggests, as a body armor against bullets and shrapnel. Consequently, the fabric has high tenacity, plus abrasion and tear resistance. You’ll commonly see ballistic nylon on the high-wear areas of a backpack, such as the bottom panel, instead of throughout the entire bag. On the downside, ballistic nylon is a thick material, making it heavier than regular nylon fabric and can look less refined than other backpack materials.

B. Ripstop Nylon

Ripstop does exactly what its name suggests — it stops the rip. Ripstop nylon utilizes a special weave of reinforced thread that is woven into a grid pattern in the fabric. If the fabric does manage to get punctured, it likely won’t continue ripping past each square of reinforced thread. Ripstop nylon is also lightweight. However, its construction tends to make crinkly sounds when the fabric moves and it tends to absorb water more than other nylon fabrics.

C. Cordura Nylon

Cordura is a brand of primarily nylon fiber, sometimes mixed with other fibers like cotton or polyester, that offers a more abrasion-resistant version of regular nylon. Used in military, workwear and everyday textiles, backpacks made from Cordura are lightweight and resistant to tears, punctures, abrasion and water. However, despite its superior abrasion resistance, some tests have shown Cordura to have a weaker tearing strength than regular nylon.

But what are the downsides to nylon? In terms of everyday use, nylon isn’t as resistant to stains or UV rays as other fabrics, making it susceptible to degradation over time if kept in the sun. Environmentally speaking, Nylon emits more greenhouse gasses compared to natural fibers. Using and washing it can release microplastics, and it doesn’t biodegrade. To reduce these downsides, you’ll see many backpacks made with recycled nylon materials.

2. Polyester

Polyester is one of the most popular synthetic fibers used in backpacks. That’s because polyester is cheap, strong, durable, hydrophobic and resistant to UV, wrinkles and stains. Polyester is more UV and water-resistant than nylon, but it’s also weaker. When polyester is used in backpacks, you might see tougher materials like leather or ballistic nylon used in high-abrasion areas. Higher-quality polyester fabric backpacks tend to use high-denier polyester yarns (i.e. thicker yarns) and/or yarns with more twist to create a fabric with greater abrasion resistance. Ripstop polyester is also used for extra durability.

3. Ultra-High Molecular Weight Polyethylene (UHMWPE)

Among the most cutting-edge backpack fabrics is ultra-high molecular weight polyethylene (UHMWPE). Although this synthetic material was commercialized in the ’50s, it was mainly used for medical backpacks, as well as military and industrial applications. That’s because UHMWPE is super lightweight, waterproof, UV and chemical resistant — and touted to be stronger than steel. However, it is the most expensive type of common backpack fabric on the market. In the past few decades, UHMWPE has made its way into backpacks under two brand names.

A. Dyneema

Dyneema is the stronger, and perhaps better known, of the two popular UHMWPE brands. Touted to be 15-times stronger than steel at the same weight, Dyneema offers a super-light, yet extremely strong, solution to the needs of outdoor and hiking backpacks. Like other UHMWPE fibers, Dyneema is UV, chemical and fungal resistant. Moreover, many Dyneema materials are waterproof: like the laminated Dyneema Composite Fabric. Other fabric options found in backpacks include Dyneema mesh and Dyneema ripstop.

B. Spectra

Spectra is another material brand made from UHMWPE fiber. It’s used in medical, nautical, ballistic and textile applications as well as backpacks. Spectra is also touted by the brand to be 15-times stronger than steel, to be more durable than polyester, and light enough to float. It has similar UV, chemical and fungal resistances as Dyneema. However, some sources say that, compared to Dyneema, Spectra is slightly weaker and can slowly stretch out under long, heavy loads.

4. X-Pac

X-Pac is a super lightweight, durable and waterproof composite material made from laminating multiple fabrics together. Originally designed as an advanced sailcloth, X-Pac has a remarkable strength-to-weight ratio and can withstand intense environmental and physical forces. The first key to its success comes from the patented X-Ply which features a diamond pattern at 22-degree angles to evenly distribute and reinforce the weight of a heavy load. Each of X-Pac’s fabric layers (such as polyester or nylon) have distinct benefits: resulting in a composite fabric that not only performs well, but looks and feels great. It is almost as expensive as UHMWPE fabrics and it is also heavier.

Common Backpack Lining Materials

While the exterior body fabric of a backpack is crucial for facing the majority of a backpack’s wear and tear, the interior fabric also serves several key purposes: added water resistance, structural support, ease of cleaning, organization, aesthetic and feel. Let’s look at a few common backpack lining materials.

Polyester

Polyester is common in children’s bags for its affordability and compatibility with colorful dyes. If polyester is used in a more durable backpack, you might see the use of ripstop polyester or a special coating for added protection. Higher denier polyester (making a heavier and stronger overall fabric) is used to line hiking and outdoor backpacks because its hydrophobic properties make it repel water and dry out faster than nylon. You’ll also see many recycled-polyester backpacks on the market today.

Nylon

When it comes to high-abrasion and high-tenacity demands, backpacks are often lined with nylon to support the friction and weight of heavy loads. This can range from rugged everyday backpacks to, travel backpacks and outdoors and hiking bags. Ripstop and high denier nylon increase durability even further. Despite nylon’s durability, it absorbs water and tends to stretch a little when wet. To make up for this, nylon almost always has a water-resistant coating. Similar to polyester, it’s easy to find recycled nylon for an eco-friendlier option.

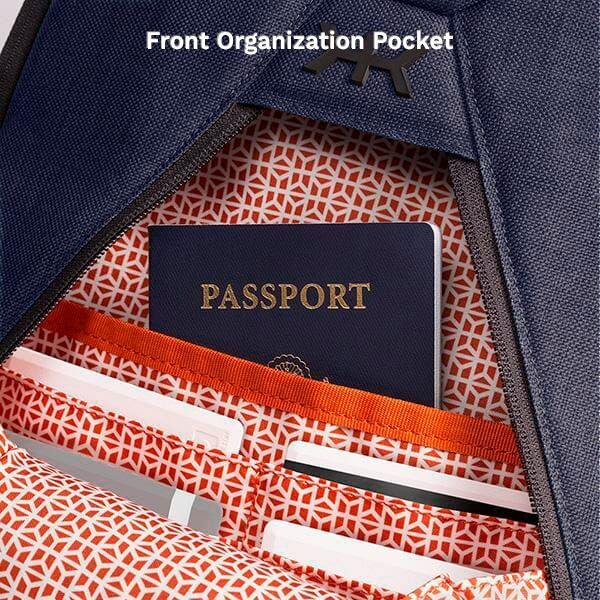

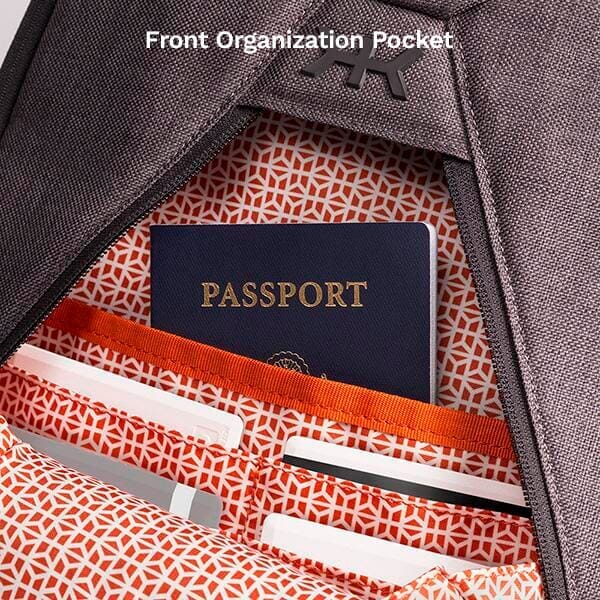

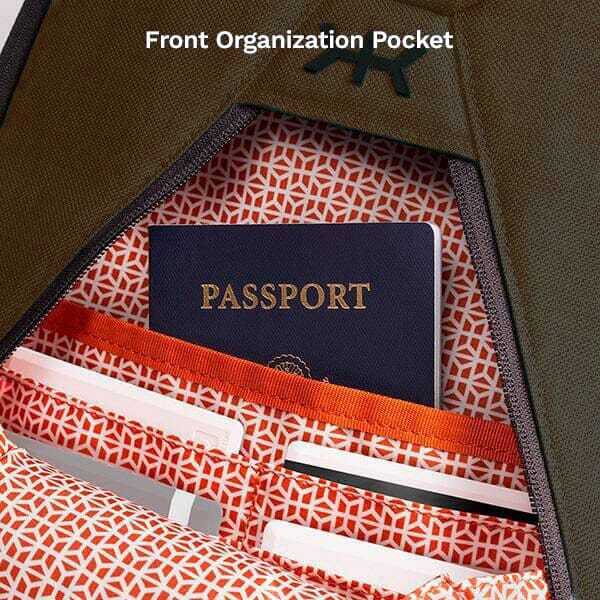

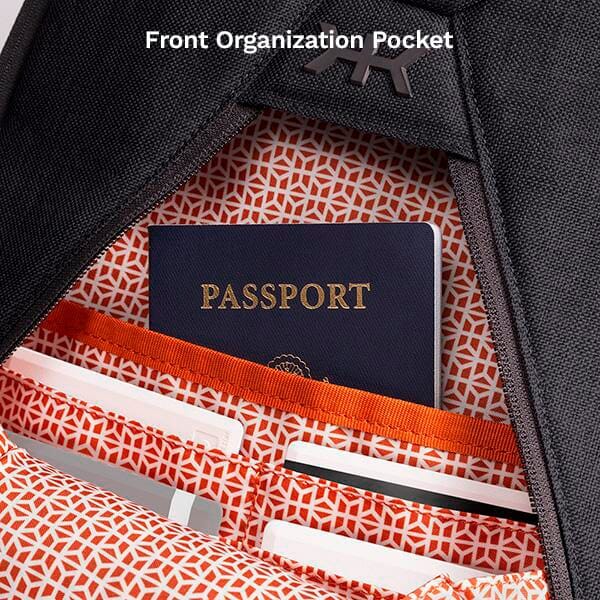

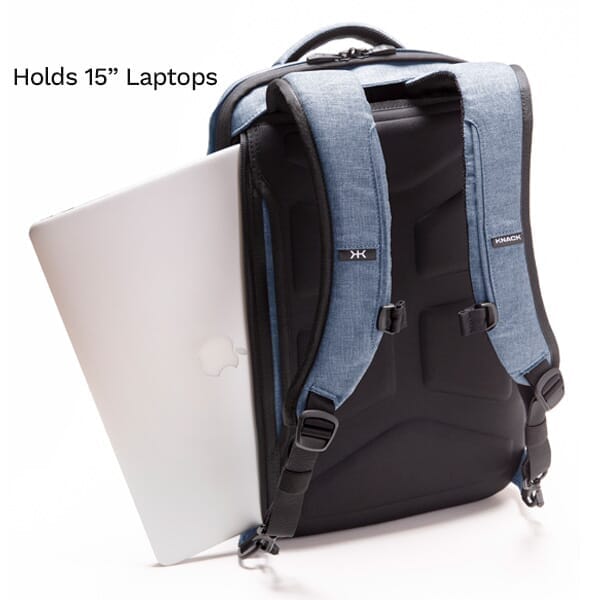

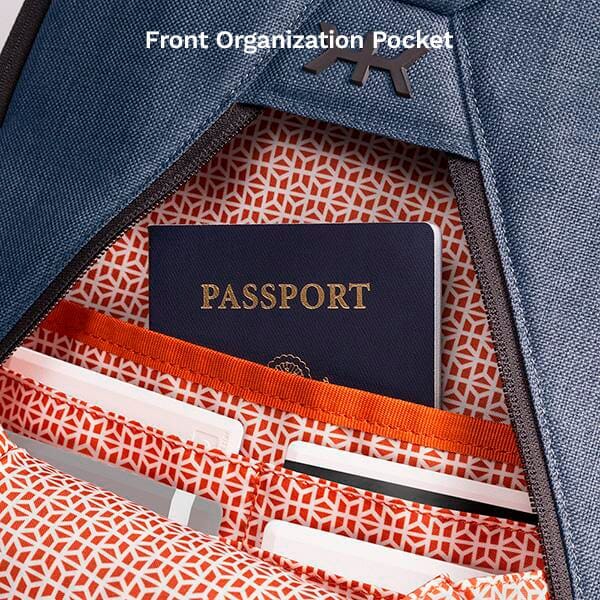

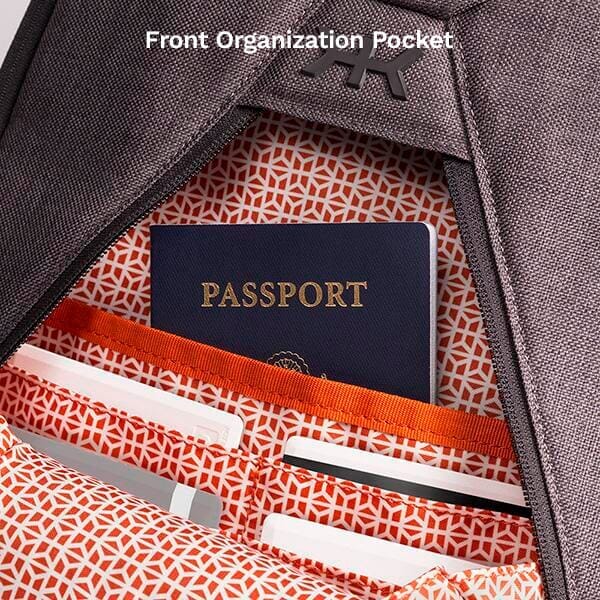

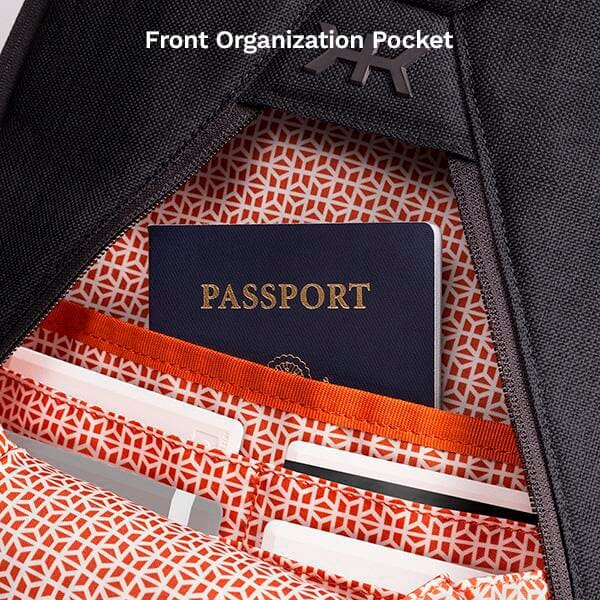

Knack Packs use custom nylon lining that is stain-resistant and anti-microbial — resulting in a durable bag that looks professional and stays clean.

MORE >> The Comprehensive Guide to Backpack Sizes and Liters

Luxury Linings

High-end luxury backpacks can be lined with a range of materials, depending on the specific style. While some may be lined with nylon or polyester, other backpacks feature leather, cotton linen, or microfiber lining. Luxury backpack linings are usually based on aesthetic and feel rather than function.

Backpack Coatings

Backpack coatings are essential for improving the feel, durability, water-resistance, and overall performance of the backpack. They protect the fabric from moisture, abrasions, and environmental damage, helping the pack withstand harsh conditions. More often than not, a backpack has a special coating. Here are a few popular coatings and their benefits.

Waterproof Coatings

Polyurethane (PU): Enhances water resistance by adding a thin, flexible layer to fabrics like nylon or polyester.

Silicone: Provides excellent waterproofing, making fabric water-repellent and durable.

Durable Water Repellent (DWR): Surface treatment for water resistance, causing water to bead and roll off in light rain.

Polyvinyl Chloride (PVC): Heavy-duty waterproof coating for maximum protection against water.

Thermoplastic Polyurethane (TPU): Offers strong waterproofing with flexibility and environmental advantages over PVC.

Durability Coatings

Polyurethane (PU): Improves longevity, protecting the fabric from abrasions and wear.

Silicone: Enhances fabric durability, especially for lightweight outdoor gear, with added UV resistance.

Polyvinyl Chloride (PVC): Provides extreme durability, tear resistance, and toughness for rugged conditions.

Thermoplastic Polyurethane (TPU): Strong and resistant to abrasions, oils, and chemicals, improving overall durability in harsh environments.

Anti-Microbial Coatings

Silver Ion Coating (Agion): Uses silver ions to disrupt bacterial cell walls, providing long-lasting antimicrobial protection against bacteria, mold, and mildew. Ideal for gym backpacks or in humid environments.

Microban Coating: Inhibits the growth of bacteria, mold, and mildew, preventing odors and stains. Often applied to the interior linings of backpacks, especially in high-moisture areas.

Antimicrobial Polyurethane (PU): Some variations of PU coatings include antimicrobial agents to protect against bacteria and mold, making them suitable for both exterior and interior backpack surfaces.

Zinc Pyrithione Coating: A broad-spectrum antimicrobial that prevents the growth of bacteria and fungi, typically applied to fabrics exposed to moisture.

Backpack Hardware

While a backpack’s fabric is key, it is also important to understand the characteristics of the hardware used. Here is a breakdown of the most common materials used for backpack hardware: including zippers, buckles, adjusters, and more — along with the pros and cons of each.

1. Zippers

Backpack zippers play a crucial role in ensuring durability, ease of access, and security for your gear. High-quality zippers, such as those from YKK, SBS, and RiRi, are well-known for their reliability.

YKK, one of the most trusted brands, uses materials like nylon, polyester, and zinc alloy to create zippers that are both flexible and durable. SBS offers a wide range of materials including resin and metal for a sturdy design. RiRi, a premium brand, often uses stainless steel and aluminum for their luxury and high-performance zippers, prized for their smooth glide and longevity.

Pros and Cons of common backpack zipper materials:

Metal Zippers: Aluminum, brass, or nickel.

- Pros: Strong, durable, and resistant to wear.

-

Cons: Heavier and can corrode or rust over time.

Plastic Zippers: Polyacetal or other thermoplastic polymers.

- Pros: Lightweight, rust-resistant, and smooth to operate.

-

Cons: Not as durable under heavy strain, and can crack in very cold weather.

Nylon Coil Zippers: Nylon teeth on a fabric tape.

- Pros: Flexible, lightweight, and reliable. Can bend without damaging the teeth.

- Cons: Less durable than metal under high tension.

2. Buckles

Backpack buckles are essential components that help secure straps, adjust fit, and keep gear organized. Top brands like Duraflex, ITW Nexus, and Woojin offer high-quality buckles known for their strength and durability. These brands commonly use materials like acetal (POM), which is a thermoplastic known for its toughness, lightweight properties, and resistance to wear and extreme temperatures.

Duraflex and ITW Nexus buckles are widely used in outdoor and tactical gear, while Woojin is known for its sleek, ergonomic designs — making them reliable choices for both everyday use and heavy-duty backpacks.

Pros and Cons of common backpack buckle materials:

Plastic Buckles: Polyoxymethylene (POM), polypropylene.

- Pros: Lightweight, corrosion-resistant, cost-effective.

- Cons: Can break under extreme pressure or cold.

Metal Buckles: Aluminum, stainless steel, or zinc alloy.

- Pros: Durable, withstand high loads, and offer a premium feel.

- Cons: Heavier and may corrode over time (though stainless steel is rust-resistant).

3. Adjusters

Backpack adjusters are crucial for customizing strap lengths and securing webbing, allowing for a comfortable and secure fit. Leading brands like Duraflex, Woojin, and ITW Nexus are well-regarded for producing high-quality adjusters. These brands often use materials such as acetal (POM) or nylon, both of which offer excellent durability, impact resistance, and lightweight properties.

Duraflex and Woojin adjusters are commonly found in hiking and tactical backpacks, known for their smooth operation and reliable grip on straps, while ITW Nexus is favored for its robust and versatile designs that can withstand heavy loads.

Pros and Cons of common backpack adjuster materials:

Plastic Adjusters:

- Pros: Lightweight and economical.

- Cons: May weaken and break under stress.

Metal Adjusters:

- Pros: Extremely durable, able to withstand high tension.

- Cons: Heavier and more prone to rusting, unless made from stainless steel.

4. G Hooks, O Rings, & D Rings

Backpack G hooks, O rings, and D rings are versatile attachment points used to secure gear, straps, and accessories. Brands like ITW Nexus, Duraflex, and Woojin are known for producing high-quality versions of these components.

G-hooks, often made from materials like acetal (POM) or stainless steel, provide quick and adjustable fastening. O-rings and D-rings, typically crafted from aluminum or steel for strength, are used for organizing gear or attaching accessories. These components offer durability and flexibility, commonly used in tactical, hiking, and outdoor backpacks for both lightweight and heavy-duty applications.

Pros and Cons of common backpack G-hook, O-ring, and D-ring materials:

Plastic Rings and Hooks:

- Pros: Lightweight, easy to manufacture.

- Cons: Lower load capacity and more likely to crack.

Metal Rings and Hooks:

- Pros: Durable and able to handle higher tension.

- Cons: Heavier and prone to corrosion without proper treatment.

5. Cord Locks

Backpack cord locks are small but essential components used to secure drawstrings or cords, commonly found on cinch closures or adjustable straps. Leading brands like ITW Nexus, Duraflex, and Woojin produce high-quality cord locks that ensure a tight grip and prevent cords from slipping.

These locks are typically made from durable materials like acetal (POM) or nylon, known for their strength, lightweight nature, and resistance to wear and temperature extremes. Cord locks are crucial for keeping items securely fastened and providing easy adjustments in outdoor, travel, or sports backpacks.

Usually made from plastic or metal with a spring mechanism.

Plastic Cord Locks:

- Pros: Lightweight and easy to use.

- Cons: Can wear out or break under heavy use.

Metal Cord Locks:

- Pros: Very durable and long-lasting.

- Cons: Heavier and more expensive.

Fabric Specs & Metrics

While it’s important to understand the different types of backpack fabrics, fabric coatings and hardware, it’s also helpful to know how fabric specifications and metrics affect a backpack’s weight, durability and tenacity. Here are a few specs and metrics to help inform your ultimate backpack decision:

1. Fabric Density

This refers to how tightly fibers are woven together in a fabric and is usually measured by the weight of a fabric in a given volume of fabric. Density impacts the strength and durability of the material. Higher density fabrics are tougher and more resistant to wear and tear, making them ideal for rugged backpacks. However, they are also heavier.

2. Grams Per Square Meter (GSM)

GSM, the common measurement for fabric density, captures the weight of the fabric per square meter. Heavier fabrics (higher GSM) are generally more durable and resistant to damage but may add weight, while lower GSM fabrics are lighter and more flexible but less durable.

MORE >> The Comprehensive Guide to Backpack Sizes and Liters

3. Denier (D)

Denier measures the thickness of the individual fibers in the fabric. A higher denier indicates thicker, more durable fibers, which can offer better resistance to abrasions and punctures. Lower deniers, while lighter, can be less durable but are obviously lighter. However, denier by itself is not a measure of strength: you also need to consider fabric density, thread count, and yarn twist. Higher measures of each of these measurements can create a more durable fabric with a lower denier yarn.

4. Tenacity

This refers to the strength of the fabric, specifically its ability to resist breaking under tension. High-tenacity fabrics ensure the backpack can handle heavy loads and rough conditions without tearing.

5. Stitching

The quality of stitching affects the structural integrity of a backpack. Double or reinforced stitching adds strength to stress points, like straps and zippers, preventing seams from unraveling under load or extended use.

6. Thread Count (T)

Thread count refers to the number of threads per square inch of fabric. Higher thread counts result in tighter, smoother, and often more durable weaves, which can enhance the fabric's resistance to tears and abrasions.

Deciding Which Backpack Material Is Right for You

We understand that all the information in this guide can be overwhelming. So we pulled together the following list to help narrow down which material is best for how you primarily use your backpack.

1. Kids

Common backpack materials for kids prioritize affordability, durability, and style:

- Cotton: Soft and breathable but not very durable or water-resistant.

- Polyester: Lightweight, affordable, holds color well, and water-resistant.

-

Hemp: Eco-friendly and strong but less water-resistant.

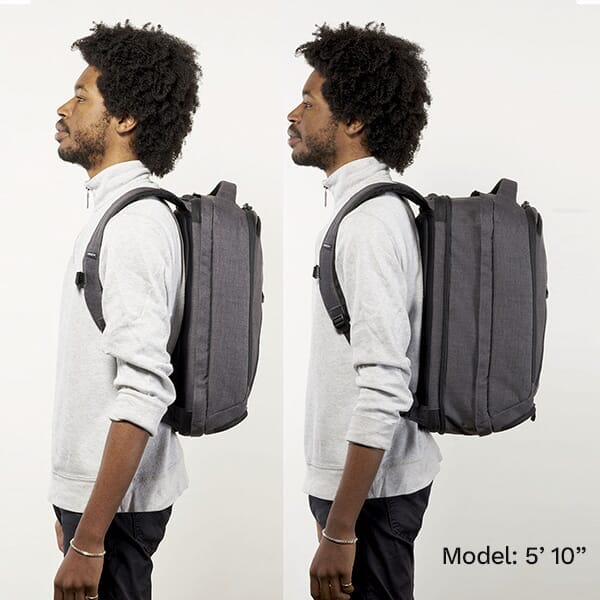

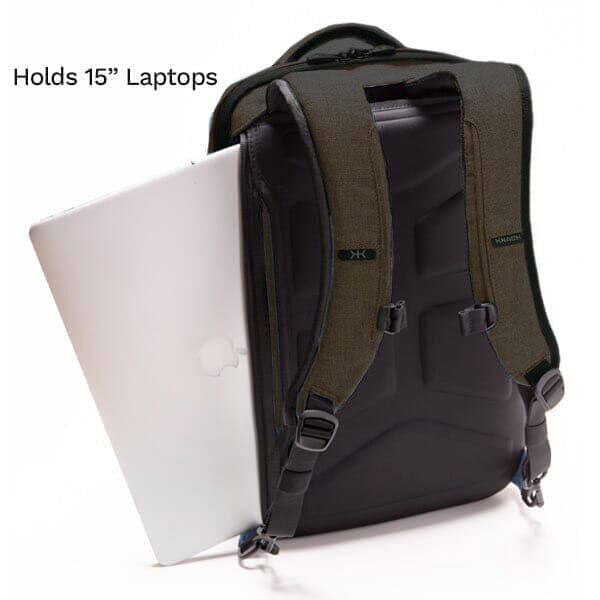

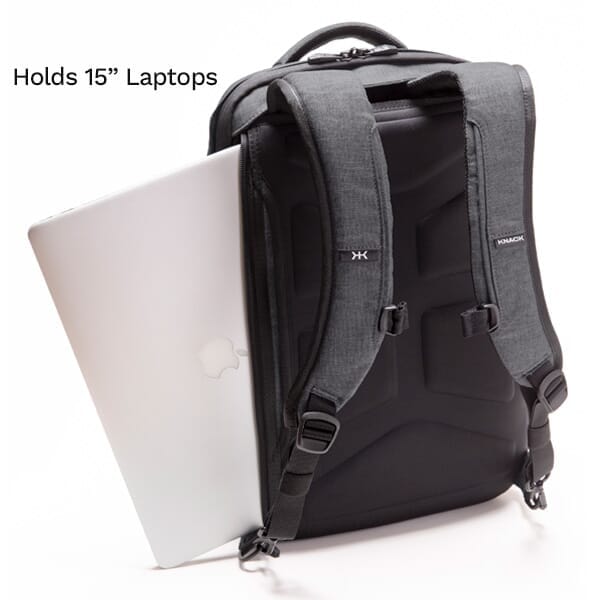

2. College, Work, Business Travel

These backpacks need to be professional, durable, and functional:

- Leather: Sleek and durable, used for a premium look but heavier.

- Nylon: Tough and abrasion-resistant, ideal for business or travel.

-

X-Pac: Lightweight, waterproof, and durable for travel.

MORE >> The Modern Duffel: Expandable & Convertible for Seamless Travel

3. Hiking and Camping

Outdoor backpacks require durability, water resistance, and low weight:

- Ripstop Nylon: Tear-resistant and lightweight, great for hiking.

- Cordura: Extremely durable, ideal for rough environments.

- Dyneema/Spectra: Ultra-light, waterproof, and highly durable for serious hiking.

- X-Pac: Waterproof and lightweight, suited for high-end outdoor gear.

FAQs:

What is the toughest backpack material?

- Ballistic Nylon: Thick, tightly woven, and highly resistant to wear and tearing, originally made for military use.

- Dyneema: Ultra-light, with an incredibly high strength-to-weight ratio, and highly resistant to tearing and weather.

What are the most eco-friendly backpack materials?

- Hemp: Highly sustainable due to its low water usage, minimal pesticide needs, fast growth, and biodegradability, making it an eco-friendly and durable material.

- Organic Cotton: Grown without harmful chemicals, it's biodegradable but requires significant water and land resources, making it less sustainable than hemp.

- Recycled Polyester (rPET): Reduces plastic waste by reusing existing materials, but still relies on fossil fuels and is non-biodegradable, making it less sustainable than natural fibers.

What materials are backpack shoulder straps made of?

- Nylon Webbing: Strong, lightweight, and abrasion-resistant, often used for the main structure of straps. It holds up well under heavy loads.

- Polyester Webbing: Similar to nylon but more UV-resistant, making it a popular choice for outdoor backpacks where sun exposure is common.

- Foam Padding: Straps often have foam inside, like EVA foam or closed-cell foam, to provide cushioning and comfort.

- Mesh Fabric: For added breathability, straps may be lined with mesh to reduce sweating and improve airflow.

What fabrics are used in school bags?

- Polyester: Lightweight, durable, and affordable, polyester is water-resistant and holds color well, making it ideal for vibrant, everyday school backpacks.

- Nylon: Known for its strength and durability, nylon is resistant to wear and tear, making it suitable for handling heavy books and frequent use.

- Canvas: A heavy-duty cotton fabric, canvas is tough and long-lasting, offering a more rugged, classic look, though it is heavier than synthetic fabrics.

- Recycled Polyester (rPET): Made from recycled plastic bottles, rPET is eco-friendly while maintaining durability and water resistance, making it popular for sustainable school backpacks.

A final word on what backpack materials are for you

Whether you’re on the hunt for a tech backpack for everyday use, or an expandable backpack for travel, it’s important to understand the different types of materials and hardware on each type of bag.

Now that you have a better understanding of what backpacks are made of, we hope that this comprehensive guide has empowered you to make a choice about what backpack material is best for you.